Hydraulic Cylinder Guide: How to Size a Hydraulic Cylinder

Hydraulic machinery and equipment are the workhorse of many manufacturing, agricultural, construction, forestry, and mining industries. Knowing how to size a hydraulic cylinder is critical not only for production and profit, but also for safety, efficiency, and equipment performance.

In this article, we will cover how to size a replacement hydraulic cylinder, along with information on mounting configuration and pressure capabilities.

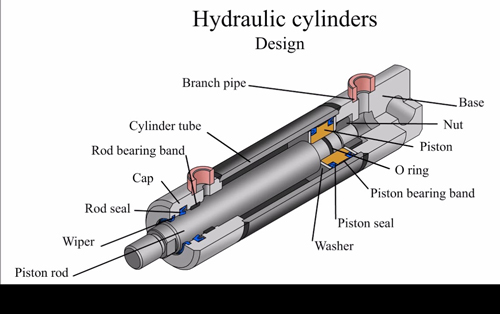

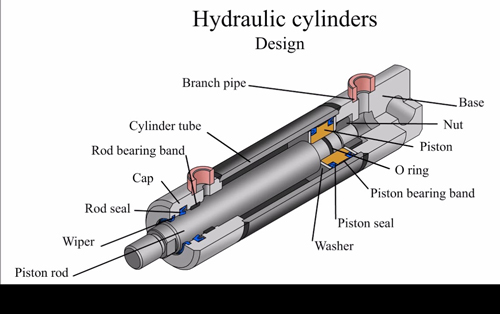

If you’re replacing a hydraulic cylinder with a piston, you’ll need to measure the piston’s diameter. This is also sometimes referred to as the cylinder bore diameter.

To obtain the cylinder bore diameter, simply measure either the inside diameter of the cylinder tube or measure the actual piston diameter if the equipment has already been disassembled. If the equipment is still assembled, you will need to measure the cylinder’s outside diameter and then subtract it by the thickness of all tubing walls.

Next, to measure the rod diameter, you’ll need a precision micrometer or caliper. With either of these tools, you’ll measure the rod thickness. Be sure to measure twice, because an inaccurate piston rod dimension can cause rod bending and machine failure in the future.

In this next step, you will take multiple measurements (be sure to have your tape measure handy). First, you need to measure the full stroke of your cylinder. Stroke is the rod’s full extended length subtracted by its retracted length.

Extended length is the distance between a fixed point on your cylinder and its maximum extended position. The retracted length is the distance between a fixed point on your cylinder and its full retracted position.

Be sure to separately record the retraction and extension lengths, as you will also need this information when ordering a replacement. If your hydraulic cylinder is still functioning well and already installed, be sure to read over the appropriate lock-out tag-out requirements.

When sizing a hydraulic cylinder, you will also want to determine how the hydraulic cylinder is mounted within the unit. You can refer to the original equipment manufacturers (OEM)- provided information or refer to the National Fluid Power Association (NFPA) publication of standard mounting types.

The hydraulic cylinder ends and mounting can be either flanged, side lug mounted, pivot mounted, or trunnion mounted, or they can have tie rod mounts. Most industrial cylinders are flange mounted, while mobile equipment may feature pivot mounting.

The hydraulic cylinder’s working pressure will vary depending on the type of hydraulic system and the equipment application. The maximum pressure released by the hydraulic pump can be found in the manufacturer’s operating manual or measured at the cylinder ports.

The maximum pressure capacity of a light- or medium-duty industrial hydraulic cylinder is typically up to 1,500 PSI or 3,000 PSI. But, higher pressure duties of up to 10,000 PSI are available for heavy-duty equipment.

SAM-registered and ISO 9001-certified, Yates has been a leading hydraulic cylinder manufacturer for over 50 years. We carry a wide range of tie rod, welded, and mill duty replacement cylinders, and will help you find the right product for your needs. If you still have questions on how to size a hydraulic cylinder, reach out to our experts today.