Hydraulic Cylinder Guide: Seal Kits

Seal kits are used to close gaps between components in hydraulic cylinders. Closing these gaps is essential because seals are responsible for maintaining hydraulic pressure and preventing contaminants in fluid power systems.

If you’re thinking about purchasing a hydraulic cylinder seal kit, you most likely have a few questions. In this article, we’ll outline what you need to know before you make your purchase.

Short answer: no.

There are many types of hydraulic cylinder rebuild kits. Each hydraulic cylinder has unique rod and bore diameters, stroke length, cylinder length, pressure flow requirements, etc. Some of the different types of hydraulic cylinder seal kits include standard, loaded lip, cast-iron piston rings, and fluorocarbon.

The type of kit you need depends on the piston rod’s stroking speed, fluid media, fluid pressure range, and more. You must also be sure that the seals in the kit are the right size.

Sizing a hydraulic cylinder seal kit is a straightforward process. You need a tape measure and calipers to take measurements. Take your time and be meticulous.

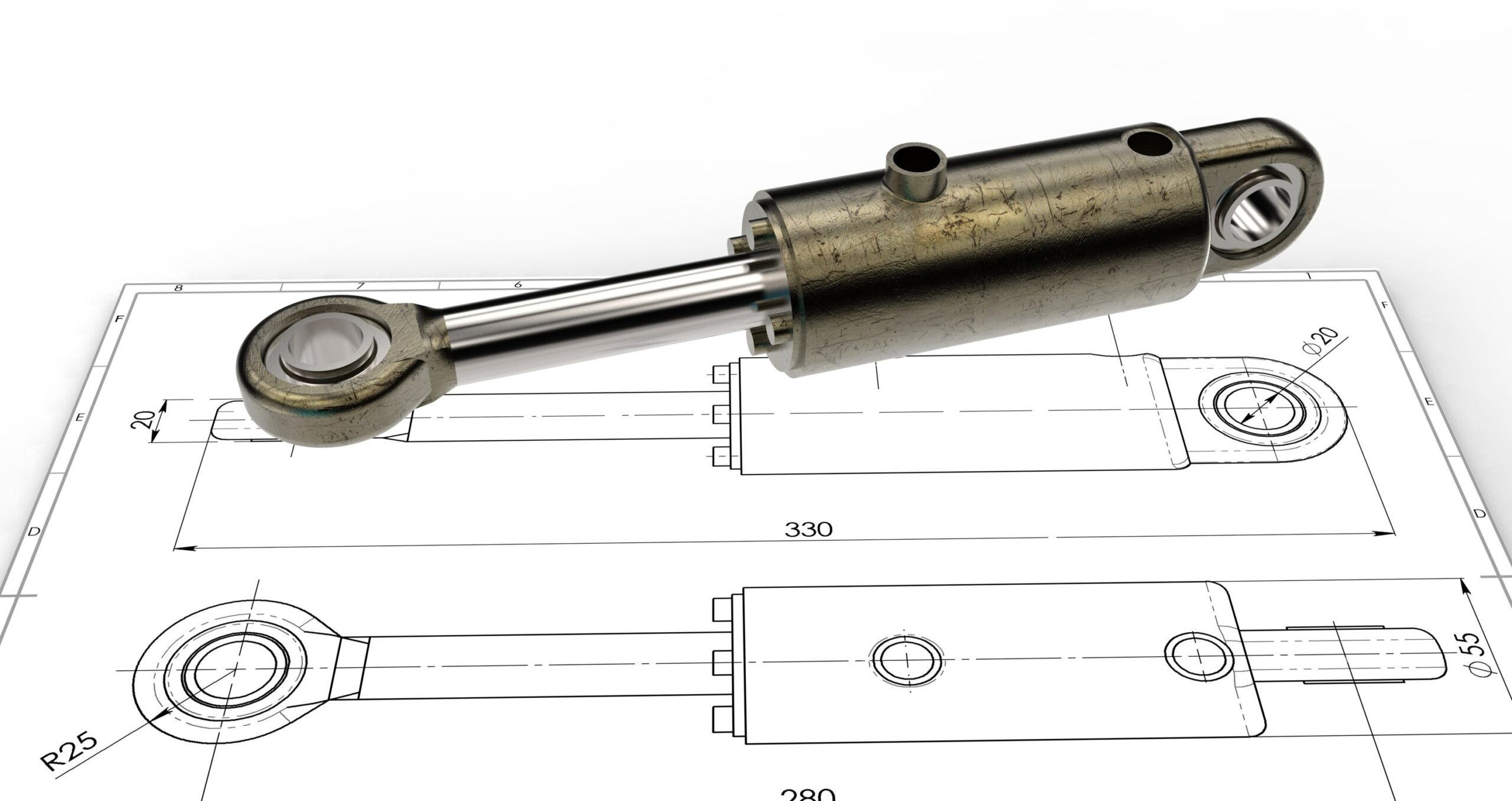

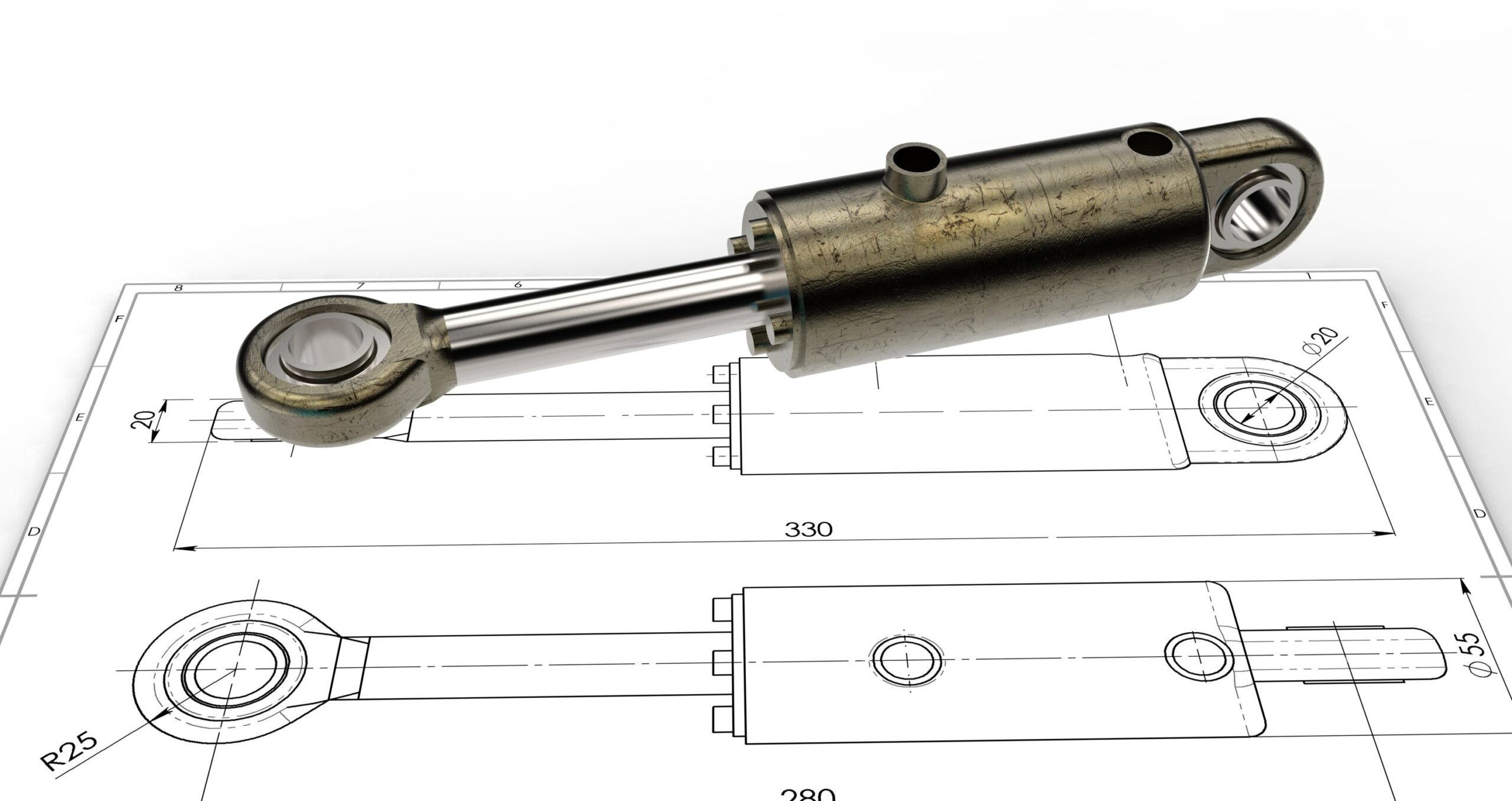

Determine your cylinder’s bore, which is the interior diameter of the cylinder. Measure bore with a tape measure stretched across the cylinder’s inner barrel.

The piston rod is normally a chrome-plated, circular piece of hardened steel that’s attached to the piston. Measure its diameter with outside calipers.

The retracted length of your cylinder is the distance between the centers of its pin holes when the cylinder is totally closed (retracted). Your tape measure will work best for this step.

The extended length of a hydraulic cylinder is the distance between its pin holes when the cylinder is completely opened. Again, use your tape measure to obtain this.

Simply subtract your cylinder’s retracted length from its extended length. For example, if your retracted length was 12 inches, and your extended length was 34 inches, your stroke will be 22 inches.

Carefully evaluate your cylinder’s hose ports, which are where you connect hydraulic lines to deliver fluid into the cylinder. Look for any signs of abnormal wear and tear and order replacement accessories, as necessary.

The two main types of hydraulic cylinder seals are: static and dynamic. Static seals stay in one place and prevent fluid leakage in areas where there’s no movement, such as where the piston and rod join.

Dynamic seals, on the other hand, are used in parts that move relative to each other. Examples of dynamic seals include piston seals, which control the motion of the cylinder; rod and buffer seals, which manage fluid leakage and lubrication; wiper seals, which keep dirt out of the system; and guide rings, which keep everything aligned and prevent wear. Together, these seals play a vital role in the efficient operation of hydraulic cylinders.

Hydraulic cylinder seal kits are essential when you suddenly encounter an unforeseen failure. Some seal failures are easy to spot, such as oil leaking from around the cylinder, while others are more challenging.

A drop in hydraulic pressure, an overheated cylinder, loud clunking or banging noises, and higher-than-normal shaking and vibration are all signs you need to inspect your cylinder. Other potential signs of seal failure include:

If you need help selecting the right seal kit, get help from our team at Yates Cylinders. We’ve been a leading hydraulic cylinder manufacturer for over 50 years and carry hydraulic cylinder seal kits in various sizes. Some of our kits include standard, loaded lip, fluorocarbon, low-friction, and cast iron piston ring.

When you have your bore, rod, stroke, and other measurements, reach out to us via our fast and easy online contact form, and one of our representatives will get in touch with you shortly.