Hydraulic Cylinder Guide: Sizing a Replacement

There are countless sizes and types of hydraulic cylinders, which is why it’s important to size them before purchasing a replacement. If you’re not familiar with this process, keep reading. In this article, we’ll outline the process step-by-step, including any formulas and conversions that you need to know.

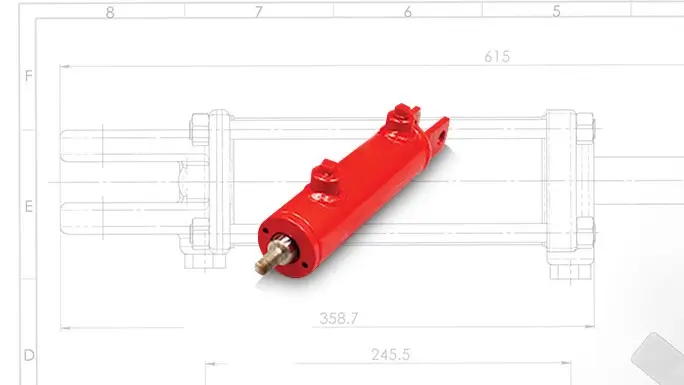

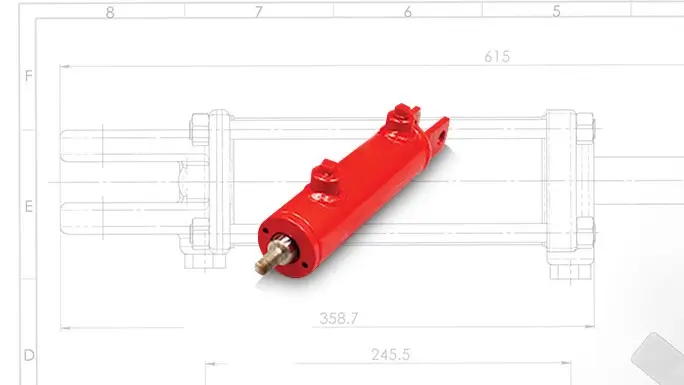

Sizing a hydraulic cylinder is a straightforward process that only requires a tape measure and calipers. Here’s a step-by-step guide:

Measure your cylinder’s bore, which is the internal diameter of the cylinder’s barrel.

Measure the diameter of the piston rod, which is the circular steel cap attached to the piston.

Measure the cylinder’s retracted length, which is the distance between its pin holes when it is fully closed.

Measure the cylinder’s extended length, which is the distance between its pin holes when it is fully opened.

Calculate your cylinder’s stroke by subtracting its retracted length from its extended length.

Carefully inspect all hose ports and other components of your hydraulic cylinder, looking for excessive wear or damage. It’s smart to order any needed replacement parts when ordering your cylinder. During your inspection, also be sure to take note of the thread type and size of your port. If any replacement hose ports are not the same thread type or size, you will need to purchase an adapter.

There are endless options for mounting hydraulic cylinders on machinery. Each original equipment manufacturer utilizes its own designs. You may need to take separate measurements if you’re working with cross tube cylinders, clevis end cylinders, tang cylinders, swivel eye cylinders, or trunnion cylinders.

The last step is to determine the working pounds per square inch (PSI) of your hydraulic fluid pressure system.

There are various hydraulic cylinder calculation formulas that you can use to make your life easier. Just plug in the variables to determine the values you require. Here are some of the most useful definitions to keep in mind.

HP = (PSI x GPM) / 1,714

F = A x PSI

MM = IN x 25.4

IN = MM x 0.03937

The above hydraulic cylinder formulas are especially useful when you have access to a hydraulic cylinder size chart, which lists out common cylinder and component dimensions.

Yates Industries manufactures and rebuilds all types of hydraulic cylinders. We have proudly offered the highest quality products at world-class prices for more than five decades. If you need to replace your hydraulic cylinder or need help selecting the right one, reach out to our team today.