Industrial Pneumatic Cylinders

What are Industrial Pneumatic Cylinders?

Industrial Pneumatic Cylinders are a lower-cost alternative to hydraulic cylinders or similar industrial applications that use hydraulic power. Instead of fluids that are used in hydraulic applications to move force, pneumatic applications use compressed air to achieve the same force movement. The use of industrial air cylinders produce less force and slower speeds in comparison with other methods, but they’re lightweight and maintenance is minimal to keep pneumatic cylinders up and running at their best.

Pneumatic actuators are widely used in manufacturing, packaging, and material handling sectors. Some forms of pneumatic actuators include clamping applications, moving applications, marking applications, and single-punch applications. The force behind these actuators is based on the size of the bore, the larger the bore, the more force is generated.

How Do Pneumatic Cylinders Work?

Pneumatic Cylinders work on air pressure and there are many types of different pneumatic cylinders that take in air and exhibit force in different ways. We will look at a typical example below:

We will look at a small hammer type industrial machine that one person can operate in a factory setting. The object of the factory worker is to put a metal piece onto a hole in the assembled part that has just come off of a metal press. This metal piece needs to be hammered into place to affix itself onto the hole and the part itself as there are only thousandths of an inch tolerance to allow the part to be hammered in correctly.

The industrial machine works on a single-acting pneumatic cylinder which comes alive once the factory worker has the assembled part ready and hits the red button on the machine. Once the worker hits the button, the cylinder springs to life and captures compressed air in one side of the chamber and forces the machine downward with enough single-stroke force to bang the metal piece through the hole and mate the piece with the assembled part. The machine’s arm slowly comes back up via a spring mechanism as the unused compressed air flows out of the escape valves on the sides of the chamber. This is why the factory worker hears a short burst of air on the downstroke and briefly on the upstroke.

Pneumatic Cylinder Components

Single-acting pneumatic cylinders have one port for air to enter the chamber which will typically be either a cap-end port or a rod-end port. The compressed air enters the chamber through these ports and the piston is moved by force through this burst of compressed air. The piston retracts by either a spring-loaded mechanism (single-acting cylinder) or the use of compressed air from the other port (double-acting cylinder). The head cap and end cap are both ends of the cylinder and they’re both sealed to keep in the compressed air. The length of extension of the piston rod is measured by stroke length.

Types Of Pneumatic Actuators

Tie Rod

Tie Rod Pneumatic Actuators are used in both small-bore and large-bore cylinders and are popular to use due to their easy disassembly to service them when needed. These types of pneumatic cylinders use steel rods to secure end caps to the barrel of the cylinder. The larger the bore of the cylinder, the more tie rods that are needed to secure the end caps.

Welded

Welded Pneumatic Actuators use strong welds to hold the end caps onto the cylinder barrel. These types of actuators are popular in packaging and manufacturing and can be used in press, transfer, mold, tilt, and latch assemblies.

NFPA

NFPA stands for National Fluid Power Association and these types of actuators are manufactured to these national standards. The nfpa pneumatic cylinders are machined to these codes and standards in relation to bore and rod diameter, piston seal types, port locations and sizes, and other facets of actuator manufacturing. The use of nfpa pneumatic cylinders are typical within industrial applications that need safety certification and assurances within their work.

Single Acting

As covered above, a single-acting actuator uses compressed air into one port to push a piston rod through the chamber with force. The return stroke is typically done with a spring-loaded mechanism to force the piston rod back to home position.

Double Acting

Double-acting actuators use compressed air in two ports versus one port of a single-acting actuator. The second port acts as the spring to force the piston rod back to home position using compressed air force versus a spring mechanism that a single-actuator would use.

Large Bore

Large Bore pneumatic actuators are used in applications that need more force versus other types of actuators. With pneumatic actuators, the larger the bore, the more force is created. Some industries that utilize large-bore pneumatic actuators are: Steel mills, Drilling, Marine, Balers, Mining, and construction equipment.

Mill Duty

Mill Duty pneumatic actuators are typically used in steel mills and foundries where a lower amount of force is needed within their applications.

Difference Between a Pneumatic and a Hydraulic Cylinder

There are stark differences between a pneumatic cylinder and a hydraulic cylinder and these differences start at the medium used to operate them. Hydraulic cylinders utilize hydraulic fluid to transmit power to the piston and are capable of much more force than a pneumatic cylinder. Hydraulics are used in applications that require a lot of power or force, typically they’re used in car lifts, braking systems in automobiles, dump truck lifts, and other applications.

A pneumatic cylinder utilizes air or gas as its main medium to transmit force through the piston. Although the force created is much lower than a hydraulic system, pneumatic systems can still put out reasonable amounts of force for most industrial applications. The applications that use pneumatic systems are typically: drills used by dentists, nail guns, air brakes in school buses and trains, air guns that blow off dust in factory assembly jobs, and other applications.

How To Choose an Air Cylinder

Air Cylinders come in all shapes and sizes and picking one out for an application can be maddening if you don’t know what you’re looking for. Therefore, you should have some factors that you need to take into consideration when selecting industrial air cylinders for an application. The materials used in the actuator should be one of the first things to look for. The durability of the actuator is partially based upon the materials that it’s made of. You have actuators that are made out of stainless steel, polymers, steel, aluminum, brass, and other materials.

How will your actuator mount to the equipment that you need it for? Will it be a typical normal mount? Or will it have to be custom-designed to fit within the application that you need it for? This is where your engineers come into the conversation to show blueprints of the machine and ways that the actuator can be fitted onto it. The trickier the fit, the harder it will be to find an actuator that will work, outside of having it custom-made which means delays in the process and more money out of pocket.

Make sure that you have enough air going into the actuator to satisfy the application that it’s being used for. Nothing will grind an assembly line down quicker than a machine that can’t keep up with demand. If the machine is struggling to take in enough air to operate at the speed of the line, then the operation will be slow and sluggish.

Dovetailing neatly with air intake is the speed of the stroke within the cylinder. The rate of air going into the cylinder combined with the length of the rod will mostly comprise the speed of operation. Make sure that the stroke speed in combination with the air intake will be enough to handle the busiest production line within your shop.

There are other facets to look out for as well including stroke length, piston force, and type of cylinder needed for your individual application.

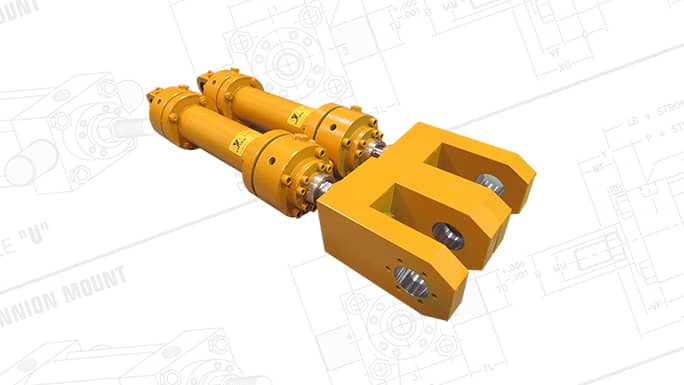

Yates

Yates Industries has been a player in the hydraulic and pneumatic cylinder game since 1972. They specialize in pneumatic cylinder manufacturing and supply for all 50 states and also excel in repairing and rebuilding air cylinders and also offer air cylinder replacement. Yates Industries are also ISO-9001:2015 certified and are proud members of the FPDA, NFPA, and the Fluid Power Society.