What Are the Different Types of Hydraulic Cylinders?

Many industries rely on the benefits that hydraulic cylinders provide. In addition to powering machines that are needed for difficult tasks, these cylinders offer exceptional accuracy and help maintain uninterrupted torque even during speed reversals.

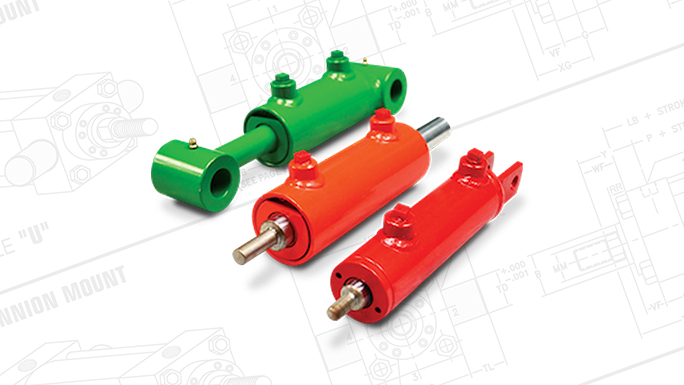

The primary differences between the different types of hydraulic cylinders involve operating pressure capacity, methods for end cap connecting, and the ability to withstand sustained temperatures during operation. In this article, we’ll cover two major types of hydraulic cylinders: tie-rod and welded, how they work, their benefits, and how to choose the best one for your application.

We’ll start with tie-rod cylinders.

Tie-Rod Cylinders

Tie-rod cylinders primarily feature rods or tie bolts that extend the length of the tube and through end cap holes. These bolts significantly enhance the stability and durability of cylinders, which eliminates the risk of the cylinder breaking down under extreme pressure.

Tie-rod hydraulic cylinders are easy to maintain and can be assembled and disassembled with conventional tools. They are also constructed according to NFPA standards to streamline interchangeability. These cylinders also work exceptionally well in applications that require low-pressure conditions and robust power.

Welded Hydraulic Cylinders

Next, welded hydraulic cylinders feature barrels that are welded to end caps, and ports that are directly welded to the barrels.

Compared to tie-rod cylinders, welded hydraulic cylinders are more modifiable, durable, and adaptable to space restrictions. They’re also well-suited for extreme environments. Lastly, welded cylinders can be custom-engineered to accommodate applications requiring precise and specific parameters.

Choosing the Right Cylinder

We’ve previously mentioned some of the benefits of tie-rod and welded cylinders, but you may be wondering which option is best for your needs. In general, you need to first understand both the mass and geometry of the objects that you need to move. Next, you need to identify the right bore and rod size for your cylinder.

Another important factor is how much space you’re working with. If you’re working with limited space, you may want to consider a welded cylinder. Additionally, if you’re using the cylinder for a high-pressure application, a welded cylinder would be the better option. However, if you’re worried about overhead costs or need a cylinder that can be easily repaired/maintained, a tie-rod cylinder is probably the best option for you.

If you need help picking out the right cylinder, consider working with an experienced company like Yates Cylinders.

How Long Do Hydraulic Cylinders Last?

Proper maintenance ensures that hydraulic cylinders operate at peak efficiency, which helps avoid costly downtimes, production delays, and unnecessary budget increases. Most well-maintained, high-quality hydraulic cylinders can continue working for as long as 10 million cycles. Reasons for hydraulic failure range from water and/or air contamination, improper fluid levels, use of inferior fluid, and human error.

What to Do With a Failing Cylinder

When you notice signs of damage in any type of hydraulic cylinder, the first step is determining the severity and cause of the issue. A repair could be as simple as replacing a seal or as extensive as a full rebuild. In general, you have two options when it comes to failing cylinders: replace or rebuild/repair. If you’re not sure which option is more cost-effective for you, ask our specialists at Yates Cylinders.

Have Questions? Learn More From Yates Cylinders

Yates Industries is a national leader in the rebuilding and manufacturing of all types of hydraulic and pneumatic cylinders. We serve all industries, including aerospace, agricultural, steel, construction, and defense. As an ISO 9001:2015-certified company, we’re committed to quality and compliance. When you turn to us, you can always expect high-quality products and services.

If you have questions about hydraulic cylinders or would like to request a service quote, please fill out our online form.