What is a Hydraulic Cylinder?

Whether you are simply wondering “what is a hydraulic cylinder?” or looking learn about hydraulic cylinder parts and how they work, or possibly are considering hydraulic cylinder repair or a hydraulic cylinder rebuild, understanding the basics of these cylinders is essential. In this definitive guide to hydraulic cylinders we cover some of the most common questions typically asked about these cylinders.

Hydraulic cylinders, or hydraulic actuators, are used extensively in several industries, including manufacturing, construction, civil engineering and aviation. These cylinders generate mechanical force in a linear motion for a variety of applications. They are typically used for pressing, pulling, pushing or lifting something that requires exceptional force.

If you’ve ever used a hydraulic jack to raise your vehicle or operated a forklift, you’ve used a hydraulic cylinder.

Hydraulic actuators operate on the basis of Pascal’s Principle of fluid mechanics. In the 17th century, Blaise Pascal discovered that any change in pressure in hydraulic fluid results in the equal distribution of energy in every direction in the fluid chamber. This means that if you have two pistons in one container and apply X amount of pressure on one piston, an equal X amount of pressure affects the second piston.

Pascal also discovered that the pressure in a fluid chamber equals the force applied divided by the area of the chamber. This formula P=F/A is the foundation for industrial machinery worldwide. For example, take two pistons in a fluid chamber where pressure is applied to the first cylinder. If the area is five times greater than the first area, the force on the second cylinder is five times greater.

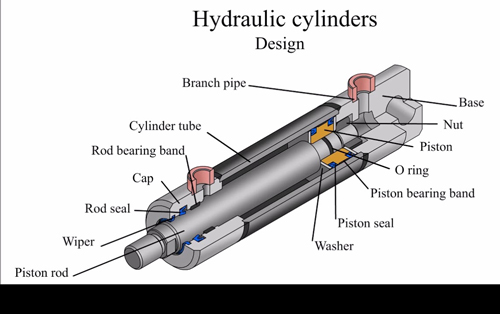

Hydraulic cylinder manufacturers can build cylinders in all sizes. From micro-hydraulic cylinders weighing a few ounces to massive industrial cylinders used with excavating shovels, hydraulic actuators generally contain the same basic components:

While hydraulic cylinders use incompressible fluid (typically mineral oil) to generate linear motion, a pneumatic cylinder relies on compressed air powered by a compressor or hand pump to create linear motion. Although both types of cylinders are used throughout the world, each type has its advantages and disadvantages.

The horsepower-to-weight ratio of a hydraulic cylinder is superior to that of a pneumatic cylinder, with hydraulics gaining one or two horsepower per pound. When it comes to power, a hydraulic cylinder can create a mechanical force that is 25 times more powerful than a pneumatic cylinder with the exact dimensions.

Unlike pneumatic cylinders that max out at 250 psi, a top-of-the-line hydraulic pump can produce 4000 psi. Since the hydraulic fluid is incompressible, hydraulic cylinders do not need additional fluid added to maintain constant force and torque. Even if the hydraulic pump and motor are located a significant distance from the operation, they can function efficiently without a noticeable loss of power.

Hydraulic cylinders are more complex than pneumatic models and require several additional components, including release valves, pumps, motors, reservoirs and heat exchangers. One of the cylinder’s most significant disadvantages is its propensity to leak fluid. Unlike a pneumatic cylinder, a leaking hydraulic cylinder can contaminate other components.

Pneumatic cylinders are far less complex than hydraulics, but they’re incredibly accurate in creating linear motion. Pneumatic actuators excel at operating in extreme temperatures and typically work within a range of -40°F to 250°F. In extreme conditions, pneumatics pose less of a fire hazard or explosion risk due to their reliance on compressed air that does not require a motor to operate. Compared to hydraulic cylinders, pneumatics are less expensive to purchase and operate.

Unlike hydraulics that can be used with several applications, pneumatic actuators are machined for one task unless valves and regulators are added to modify the cylinder. Although compressed air is cheap and widely available, it can damage the equipment when contaminated by oil or lubricant. Pneumatic cylinders are also less efficient because the compressor must constantly run even if the cylinder isn’t moving.

There are many types of hydraulic cylinders for sale, with these being the four most common:

Single acting hydraulic cylinders produce power when hydraulic fluid enters a single port and flows into the cylinder and causes the cylinder to retract. Also called push cylinders, they feature a single-acting piston that moves in one direction and requires a motor or spring to reset its position.

In double acting hydraulic cylinder models, fluid moves into one port and exits through a second port, forcing the cylinder to retract and extend. With two pressurized chambers, double-acting pistons do not require a spring or motor to operate.

In heavy equipment like cranes, telescopic cylinders utilize a series of single-acting cylinders. When one cylinder retracts, it transfers force to the next cylinder.

With two separate barrels connected by the piston rods, the tandem cylinder design achieves a significant degree of force in a small area. Tandem cylinders can be combined in stages to provide more power.

After determining the application that requires a hydraulic linear actuator, you must consider several factors before selecting the ideal actuator. The planning and design process is vital for operating an efficient hydraulic operation, and the primary elements in the process include:

Hydraulic linear actuators are used in countless applications in every corner of the globe. Compared to other actuators, hydraulic cylinders are more efficient, powerful and durable. In the mobile equipment industry, hydraulics are exclusively used on excavators, bulldozers, dump trucks, graders and loaders.

Manufacturing plants rely on hydraulic actuators to operate forging presses, injection molders, compactors and other heavy equipment.

Hydraulic equipment and machines utilize single-acting and double-acting cylinders, and each type has its advantages. Single-acting cylinders are simpler and easier to maintain than double-acting cylinders. However, with more fluid in the pressurized chamber, double-acting actuators are easier for an operator to control.

As leading hydraulic cylinder suppliers for over 50 years, we provide our clients a wide range of cylinders and repair any brand or style of cylinder. Here are some of the hydraulic linear cylinders we offer:

Along with this vast inventory of cylinders, we can also design and build a custom cylinder that meets your needs.